Fiber optic installations require a high level of accuracy to ensure optimal performance and longevity of the network. Precision tools play a critical role in this process, enabling installers to perform delicate tasks with accuracy and consistency. In this article, we’ll explore the essential precision tools used in fiber optic installations and how they contribute to the success of these projects, particularly in the context of Cyprus.

Why Precision Matters in Fiber Optic Installations

Fiber optic cables carry data through light signals, making them highly sensitive to any form of disturbance or misalignment. Even a small error during installation can lead to significant signal loss or network failure. Precision tools help minimize these risks by allowing installers to work with the exactness required for tasks such as splicing, connectorization, and testing.

Essential Precision Tools for Fiber Optic Installations

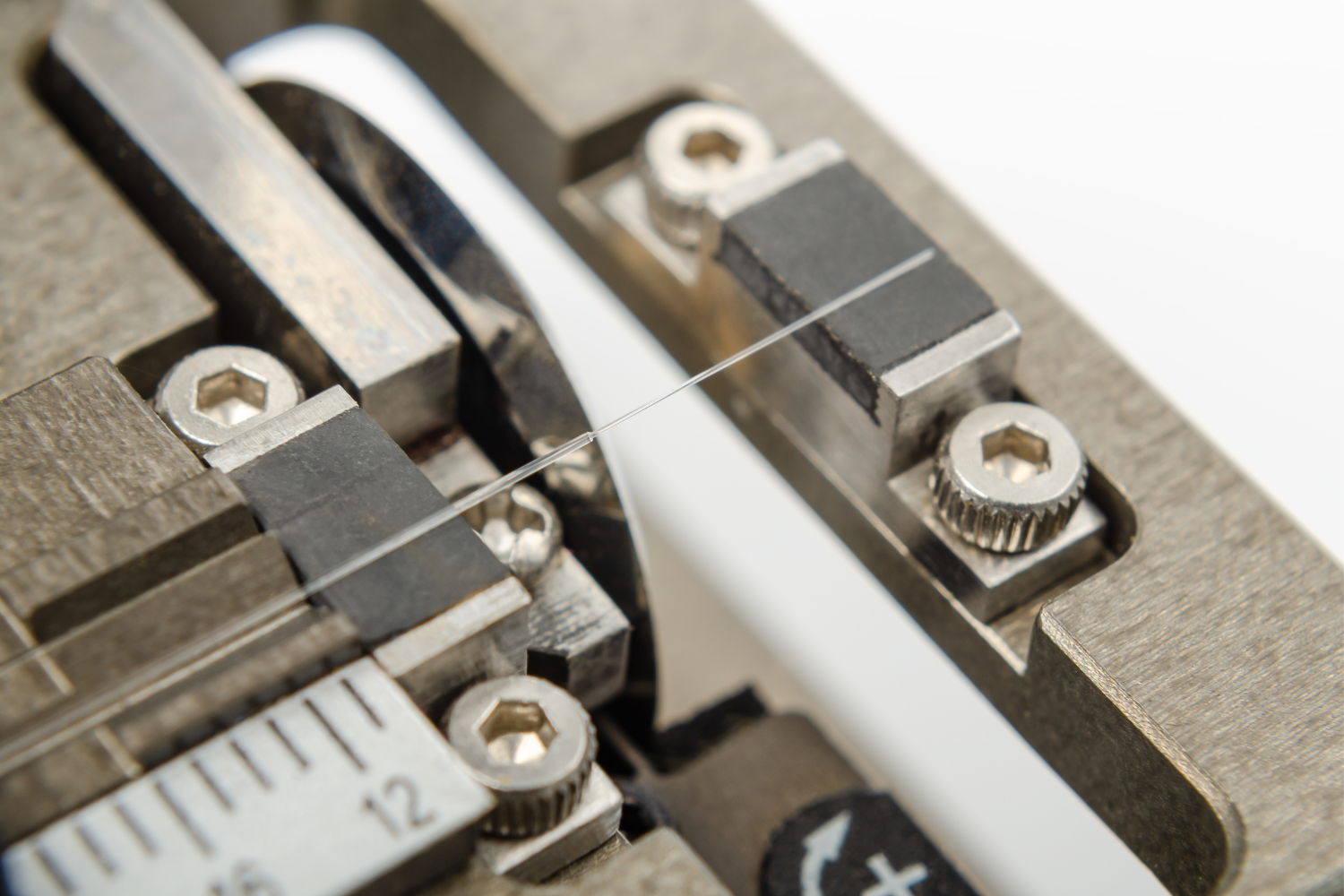

- Fiber Optic Cleaver

- Role: A fiber optic cleaver is used to precisely cut the fiber at a perfect 90-degree angle, which is essential for successful splicing and minimizing signal loss.

- Importance: Inaccurate cuts can lead to poor splices, increased attenuation, and potential signal reflection. A high-quality cleaver ensures a clean cut, leading to a more reliable network.

- Precision Stripper

- Role: This tool strips the protective coatings from the fiber without damaging the delicate glass core.

- Importance: The accuracy of the stripper is vital to prevent nicks or scratches on the fiber, which could compromise the integrity of the signal.

- Fusion Splicer

- Role: A fusion splicer aligns and fuses two fiber ends together with high precision, creating a low-loss joint.

- Importance: Proper alignment is critical for minimizing splice loss and ensuring that the light signal passes through the joint with minimal reflection or attenuation.

- Optical Power Meter

- Role: This device measures the power level of the light signal in the fiber, helping to ensure that the network meets performance standards.

- Importance: Accurate measurements are essential for verifying that the network is operating within the specified power range, which is crucial for maintaining signal integrity.

- Optical Time Domain Reflectometer (OTDR)

- Role: An OTDR tests the integrity of the fiber optic cable, identifying faults, bends, and losses along the cable length.

- Importance: Precision in detecting the exact location and nature of faults allows for targeted repairs, reducing downtime and improving network reliability.

- Connector Termination Tools

- Role: These tools are used to attach connectors to the ends of the fiber optic cables with precision.

- Importance: Properly terminated connectors are essential for minimizing signal loss and ensuring that the cable connections are secure and reliable.

- Microscope or Inspection Scope

- Role: This tool is used to inspect the ends of the fiber optic connectors for cleanliness and proper alignment.

- Importance: Even microscopic dust particles can cause significant signal loss. A precision microscope ensures that connectors are free of contaminants before connection.

- Visual Fault Locator (VFL)

- Role: A VFL emits a visible red laser light through the fiber to detect breaks, bends, or faulty splices.

- Importance: The precision of the VFL in identifying issues helps installers quickly locate and fix faults, ensuring a smooth installation process.

- Fiber Optic Polisher

- Role: This tool polishes the end faces of fiber optic connectors to achieve a smooth, flat surface.

- Importance: Proper polishing reduces signal reflection and loss at the connector interface, which is critical for high-performance networks.

- Crimping Tool

- Role: A crimping tool is used to secure connectors onto the fiber optic cable with precision.

- Importance: Proper crimping ensures that connectors are firmly attached, reducing the risk of disconnections or signal degradation.

The Impact of Precision Tools on Fiber Optic Installations in Cyprus

In Cyprus, where the demand for high-speed, reliable internet is growing, the quality of fiber optic installations directly affects the overall network performance. Precision tools are essential in overcoming the challenges posed by the local environment, such as high temperatures and humidity, which can affect fiber optic cables and connections.

Using the right precision tools not only ensures a high-quality installation but also reduces the likelihood of future maintenance issues, saving time and money. For installers in Cyprus, investing in these tools is a crucial step toward delivering top-notch fiber optic services.

Conclusion

Precision tools are indispensable in fiber optic installations, providing the accuracy needed to ensure high-performance networks. By using these tools, installers in Cyprus can achieve the reliability and efficiency required to meet the growing demand for advanced communication infrastructure.

For high-quality precision tools and expert advice on fiber optic installations, visit rapidsat.com.cy, your trusted partner in Cyprus.